Welcome Xuzhou Press Systems!

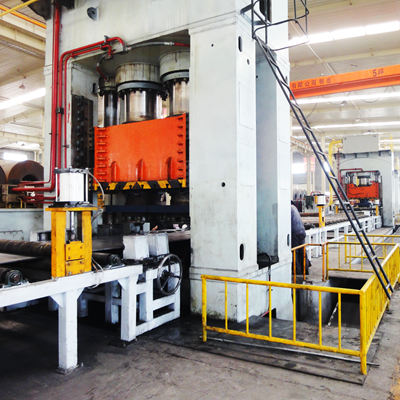

XP-L Series Blanking Hydraulic Press for Steel Wheels

产品概述:

本机主要有630吨、800吨、1600吨等多种规格,适用于车轮辐板料的落园料工艺。能满足落料最大外径630mm,最大厚度16mm。

特点:该机为标准架液压机导向结构,压机刚性好,精度高,精度保持时间长,人力机氧化的材料,经济效益可观。同时,可提高圆盘质量及尺寸精度,落出的料可直接进行旋压,保护旋轮,节省材料。

该机可通过PLC编程控制,实现压机半自动,并可与辅机实现联动,提高效率。

落料液压机辅机:由料架、滚筒、传动机构、导向对中机构、压料机构、定位机构、出料传送机构、电器控制系统组成;通过编码器‘PLC‘触摸屏可对板料输送位移进行显示及控制。可与开卷、校平机组成落料线,并可完成多种板宽(550mm,1010mm,1500mm等)料的套裁落料,以节约原材料。

Features:

This machine mainly has 630 tons, 800 tons, 1600 tons and other specifications, suitable for the falling garden material process of wheel spoke sheet. It can meet the maximum outer diameter of blanking material 630mm and the maximum thickness of 16mm.

Features: The machine is a standard frame hydraulic press guide structure, the press has good rigidity, high precision, long precision maintenance time, manpower machine oxidation material, economic benefits considerable. At the same time, the quality and dimensional accuracy of the disc can be improved, and the falling material can be directly spinned, protecting the rotary wheel and saving materials.

The machine can be controlled by PLC programming, realize semi-automatic press, and can be linked with auxiliary machine to improve efficiency.

Blanking hydraulic press auxiliary machine: composed of material rack, drum, transmission mechanism, guiding centering mechanism, pressing mechanism, positioning mechanism, discharge conveying mechanism, electrical control system; The encoder 'PLC' touch screen allows the sheet metal transport displacement to be displayed and controlled. It can form a blanking line with unwinding and leveling machines, and can complete the nesting blanking of a variety of plate widths (550mm, 1010mm, 1500mm, etc.) to save raw materials.

主要技术参数

项目 | 单位 | 型 号 规 格 | ||||||

| XP-L-800 | XP-L-1000 | XP-L-1250 | XP-L-1600 | XP-L-2000 | XP-L-2500 | |||

| 公称力 Rated force | KN | 1000 | 10000 | 12000 | 16000 | 20000 | 25000 | |

| 回程力 Return force | KN | 200 | 1200 | 1500 | 1600 | 1800 | 2000 | |

| 滑块行程 Slide stroke | mm | 600 | 600 | 600 | 600 | 600 | 600 | |

| 开口高度 Daylight opening height | mm | 1200 | 1200 | 1200 | 1300 | 1300 | 1300 | |

| 滑块速度 Slide speed | 空程 Idle stroke | mm/s | 200 | 200 | 200 | 200 | 200 | 200 |

| 工作 Pressing | mm/s | 8─20 | 8─20 | 8─20 | 8─20 | 8─20 | 8─20 | |

| 回程 Return | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | |

| 工作台尺寸 Table arer | 左右X前后(L-R)x(F-B) | mm | 1400X1200 | 1400X1200 | 1400X1200 | 1600X1200 | 1600X1200 | 1600X1200 |

| mm | 1600X1200 | 1600X1200 | 1600X1200 | 2000X1200 | 2000X1200 | 2000X1200 | ||

| mm | 1800X1200 | 1800X1200 | 1800X1200 | 2300X1200 | 2300X1200 | 2300X1200 | ||

| mm | 2000X1200 | 2000X1200 | 2000X1200 | 2600X1200 | 2600X1200 | 2600X1200 | ||

| 主电动机功率 Motor power | KW | 70 | 90 | 125 | 180 | 180 | 250 | |

INQUIRY